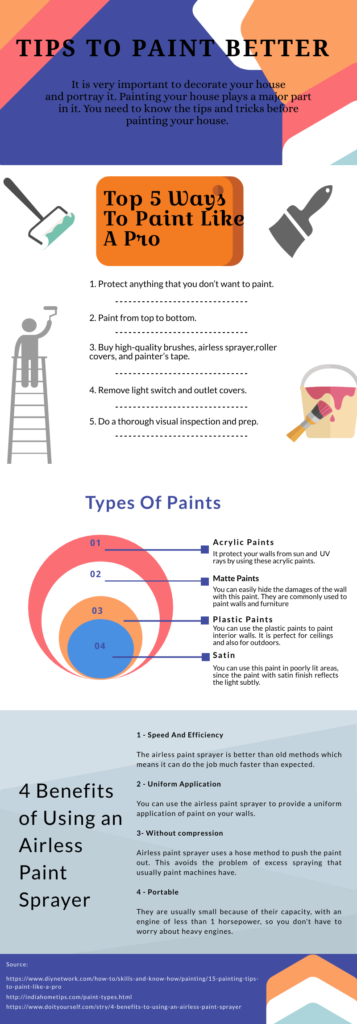

Using a compressor and a compressed airless paint sprayer to paint can save a lot of time and money, and avoid pollution caused by spray can aerosol thrusters. To paint with a compressed air sprayer, follow the instructions.

Rxtooler helps to get more info on compressed air sprayer.

Method 1

Before You Begin

1. Choose the ink and tinner of your taste.

The use of oil based enamels is recommended as they are most easily employed with a compressed air sprayer. Acrylic paints and latex paints can also be used for spraying. The addition of a suitable solvent will allow the most viscous inks to flow freely through the suction tube and spray nozzle. Before that you have to always choose a best airless paint sprayer.

2. Prepare the area where you will paint.

Place a cloth, garbage bag, newspaper, or other material on the floor and furniture so that they do not end up painted or spattered with paint. For “fixed” paintings such as the one illustrated here, you will need to protect adjacent surfaces and ventilate the room.

Protect surfaces closest to spraying by masking tape and newspaper (for example). It may happen, with an unsuspecting wind, to direct ink particles to unexpected locations.

Choose the paint and tinner to match the surface to be painted for good adhesion. This way there will be no spills.

3. To apply the paint, wear a mask, safety glasses and gloves.

These will keep you clean and protected from harmful gases, airless pint sprayer kit and particles.

4. Prepare the surface for painting.

Clean, brush or sand the application area, removing all dirt so that the surface is smooth. Before applying the paint, let the area dry. For the application of oil-based paints, it is recommended to clean the surface. For latex or acrylic paints, use soap and water yourself. Rinse a lot. Always have a look on airless paint sprayer reviews.

5. Apply a first coat of paint (optional).

You can use the sprayer to apply a primer of your choice (following the steps below as if it were a paint job) or you can simply change the primer for a primer: if you want, you can use a brush or roller. When you are done, you can sand the areas you feel you need.

Method 2

1. Turn on the air compressor.

Use some air to test your bomb. Let it create pressure for when you start your painting. The compressor must have a regulator in order to allow you to set the correct air pressure for the sprayer, otherwise fluctuations in air flow may occur.

2. Set the compressor between 12 and 25 psi.

The exact amount will vary depending on your sprayer: if in doubt, check the machine manual (or the equipment itself) for more details.

3. Place the air hose into the sprayer coupling.

Fit well to keep the hose fixed. If necessary, use thread sealing tape to better secure the nozzle. This does not apply if the sprayer and hose are equipped with quick couplings.

4. Pour a small amount of paint thinner into the reservoir.

Attached to the bottom of your spray gun is a reservoir: this is where you should dump a little tinner, enough to submerge the small siphon from inside the cup.

5. Open the sprayer air valve.

This is usually the lowest of the knobs, above the spray grip.

6. Clean sprayer with solvent.

Point the nozzle into a bucket and squeeze the trigger. It usually takes a few seconds for the system to release liquid from the glass. So at first glance, only air will come out of the nozzle. After a while you will see that the solvent will start to come out. If it does not come out, disassemble the equipment and look for anything that is blocking the flow of liquid.

7. Empty the spray cup by removing the remaining tinner.

Using a funnel as a tool, you can return the tinner to its original container. Turpentine and turpentine (two common diluents) are two flammable solvents and should only be stored in their original packaging.

People also read: 5 TIPS TO HIRE AFFORDABLE PAINTING SERVICES FOR A SINGLE ROOM

Method 3

Painting the chosen surface with the sprayer

1. Mix enough paint for your project.

After opening your paint can, mix well. Then pour enough for your project into a separate, clean container. If it has been stored in your home for a long period of time, it is a good idea to strain the paint through a special filter to remove any lumps that may have formed. These lumps can clog your sprayer siphon or metering valve, disrupting ink flow.

2. Add a suitable solvent to the paint.

The exact proportion of thinner to add will depend on your ink and spray nozzle. However, it is recommended that the paint be diluted by about 15 to 20% for good flow. Therefore, add in amount of thinner or solvent a little less than a quarter of the paint size used. Note how thin the paint will come out when you trigger your sprayer. Thereafter, does the amount of solvent most appropriately to the desired effect.

3. Fill a little more than half of the reservoir with paint, and then fit it into the spray gun.

Install the reservoir properly or it may fall suddenly during use.

4. Keep the sprayer about 5 to 10 cm away from the surface.

Practice the ideal spray, which is “side to side” or “top to bottom” in sweeping motions parallel to the surface to be painted. If you have never used this type of paint applicator before, train the process to gain a sense of balance and weight.

5. Squeeze the trigger to spray paint.

Keep sprayer moving whenever trigger is pulled. This will prevent splashing and overflow.

It is best to test your skill on a piece of wood or cardboard before the wall. Adjust the spray nozzle if necessary for a smoother, more even spray pattern.

6. Slightly overlap each layer of paint applied.

Using this spray pattern, there will be no translucent stains on your paint job. Beware of Spills and Excesses: Move the applicator fast enough to keep the paint even.

7. Fill the reservoir as needed until complete.

Do not leave paint inside the sprayer to preserve the appliance. If you want a break, remove the reservoir and spray a little solvent through the system before leaving it unused (see step 6 of “Preparing the compressor”).

8. Wait for the paint to dry and apply another coat if fundamental.

For most paints, a good, well-dry coat is more than enough. However, a second coating can offer a more durable and homogeneous finish. Sanding the surface slightly between coats is highly recommended when using varnishes, polyurethane coatings, and other glossy finishing or sealing paints between layers.

Method 4

Cleaning up the environment

1. Pour the remaining paint back into the can.

If you have a significant amount of ink left, you can return it to the can. Remember, however, that the returned ink was diluted with tinner. Next time you use it, remember that you have already added solvent to the product (indirectly).

Epoxy and catalyst inks cannot be returned; instead they should be used entirely or disposed of properly once mixed.

2. Wash the reservoir with tinner.

Wipe off any excess ink.

3. Fill the reservoir with tinner, shake a little and spray it through the gun until the jet comes out clean.

If there is still too much ink left in the system, you may have to repeat this step more than once.

4. Remove all tape and paper from your desktop.

Do this as soon as the paint dries. Leaving the tape on the surface for a long time may make it difficult to remove.

Tips

• Paint horizontally or vertically. Do not try to use both methods in the same project, as the end result may not suit (the painting’s viewing angles will not be homogeneous).

• Read the instructions or operator’s manual of your sprayer. You should be familiar with the capacity, viscosity, and type of ink your equipment supports. The photos in this article can help with this process: keep in mind that the first valve regulates air volume and the lower valve regulates ink flow. At the spray nozzle there is an adjustable ring that, when operated, changes the nozzle pattern (to vertical or horizontal).

• Always clean sprayer after use. For oil based paints, you can use acetone or varnish solvent.

• Using a compressed air spray instead of aerosol cans allows you to paint with custom colors, reduce air pollution and save money. Unfortunately, however, it is not a completely sustainable alternative, as solvents also release environmentally harmful vapors;

• Mix, if possible, enough paint for the complete paint job. Remember that each blend will generate a slightly different color.

• Use a catalyst for automotive paint finishes. This product is specially formulated to accelerate drying time without affecting the finish, color or paint finish.

• Use hot water as a solvent in water-based paints (at a temperature of about 50 degrees C). You only need to solve at 5% this way (this means you must put a solvent measure equivalent to 5% of the paint measure used);

• You can purchase a filter for your sprayer by removing impurities from the paint.

Banner Image by Free-Photos from Pixabay